Vertical Farm Development Project

Vertical Farm Development Project

The optimal farm construction

is possible in any environment.

With years of accumulated expertise,

we provide the optimal vertical farm system tailored to all environmental conditions.

Implementation Process

- Site assessment and design

- Automated seedling system installation

- System stabilization

Optimal configuration derived from years of research

| Configuration per Cube |

EA |

| 30-pyeong sized cube |

1 |

| Air conditioner |

2 |

| 4-stage smart rack |

32 |

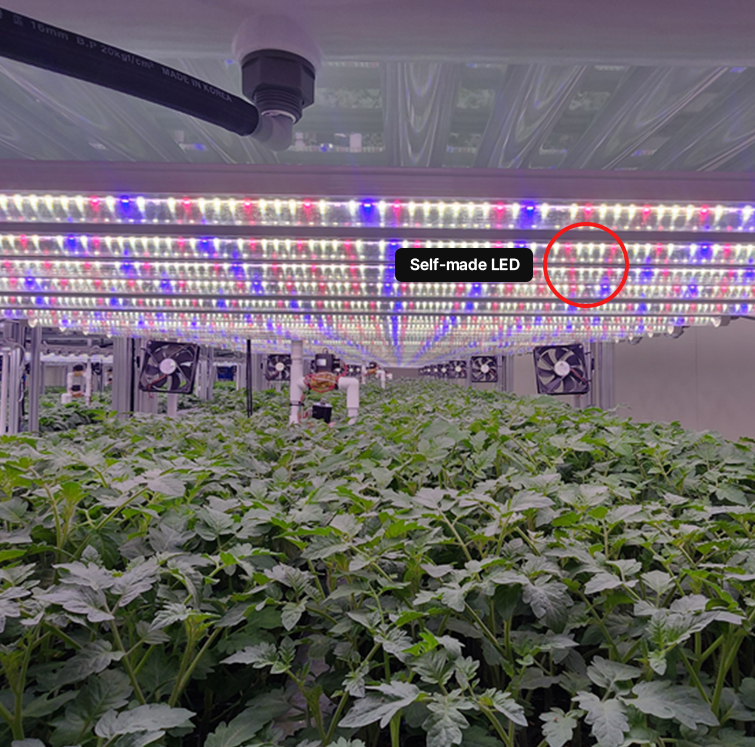

| Self-developed LED for seedlings |

1280 |

| Humidifier |

2 |

| Air circulation fan |

4 |

| Water supply and drainage system |

2 |

| External air intake and exhaust system |

8 |

| Smart electrical box |

1 |

| AI-based operation software |

1 |

| Inventory and work management software |

1 |

| Temperature and humidity sensor |

2 |

| Corridor ladder |

2 |

A system enabling growth in optimal conditions

365 days a year without exposure to pests and diseases

System 01

Optimal Light

Source Settings

- Provides uniform light quality tailored to each crop variety (spectrum 300~600 PPFD)

- Optimizes light exposure duration according to seedling growth stages

- Adjustable height according

to seed and plant growth (Adjustable up and down between 15 cm and 45 cm)

LED photo at

maximum raising

- The height adjusts in 10 steps from the lowest to the highest position, ensuring sufficient light throughout the seedling growth stages.

- Light height can be adjusted separately for fruit vegetables and cucurbits, and for more precise control, adjustments can be made by individual crop varieties.

System 02

Optimal Temperature

and Humidity Control

- Controls temperature and humidity according to germination stage, seedling growth stage, and crop type.

- Ensures stability through dual air conditioning systems.

- Promotes growth and suppresses overgrowth by regulating temperature and humidity.

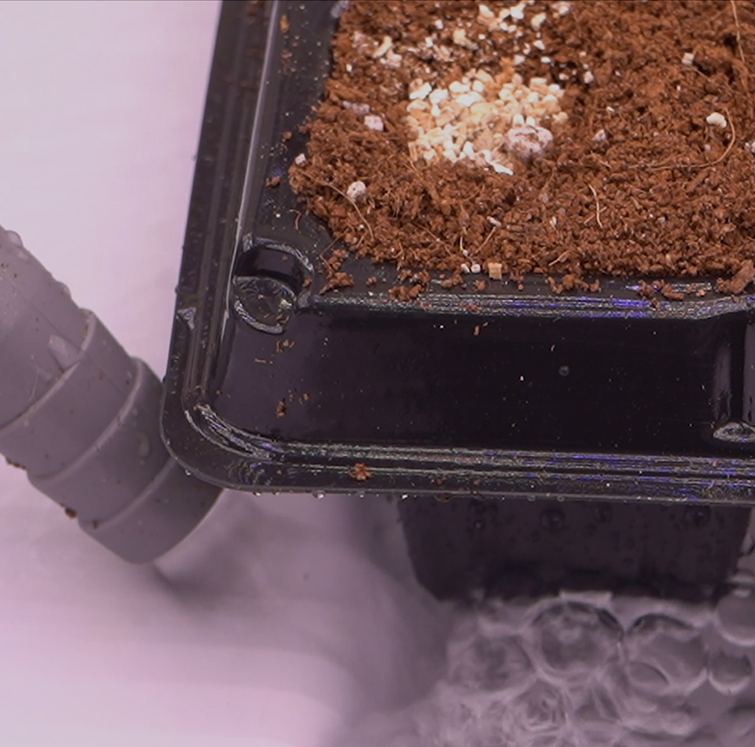

System 03

Automated Nutrient Solution

Preparation and Irrigation System

- Maintains consistent irrigation volume and timing through automated control

- Optimizes root development via sub-irrigation

- Enables nutrient solution recycling with a recovery system

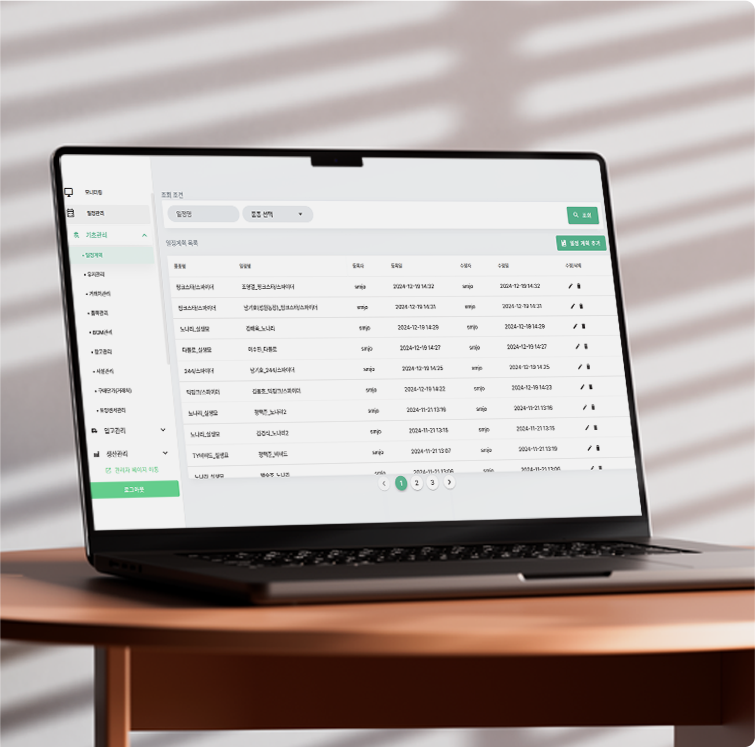

System 04

Real-time Monitoring

and Control System

- Web-based program accessible via PC, tablet, and smartphone

- Enables detailed precision control comparable to PRIVA, with high-quality seedling growth recipes

- Provides automatic alert notifications for sensor malfunctions and temperature/humidity abnormalities

System 05

Order and Inventory

Management System

- Provides inventory management and real-time stock management system

- Provides order management and sales management system

- Provides order processing status monitoring system

Annual Number of Seedlings Produced and Sales Revenue

| Annual sales |

256,000,000won(₩) |

|

| Category |

Quantity |

Remarks |

| Number of racks |

32 |

|

| Number of tiers per rack |

4 |

|

| Number of trays per tier |

8 |

|

| Number of trays per cube |

1,024 |

32*4*8 |

| Number of seedlings per 50-cell tray |

51,200 |

1 cultivation cycle |

| Number of seedlings per 10 cycles |

512,000 |

10 cultivation cycles |

| Price per seedling |

500won(₩) |

|