Seedling Equipment

Seedling equipment

Efficiency is maximized through

automation equipment.

Processes in the seedling stage that require a lot of manpower are optimized

for efficiency through automation equipment.

Main equipment

- Seeder

- Sorter

- Grafting machine

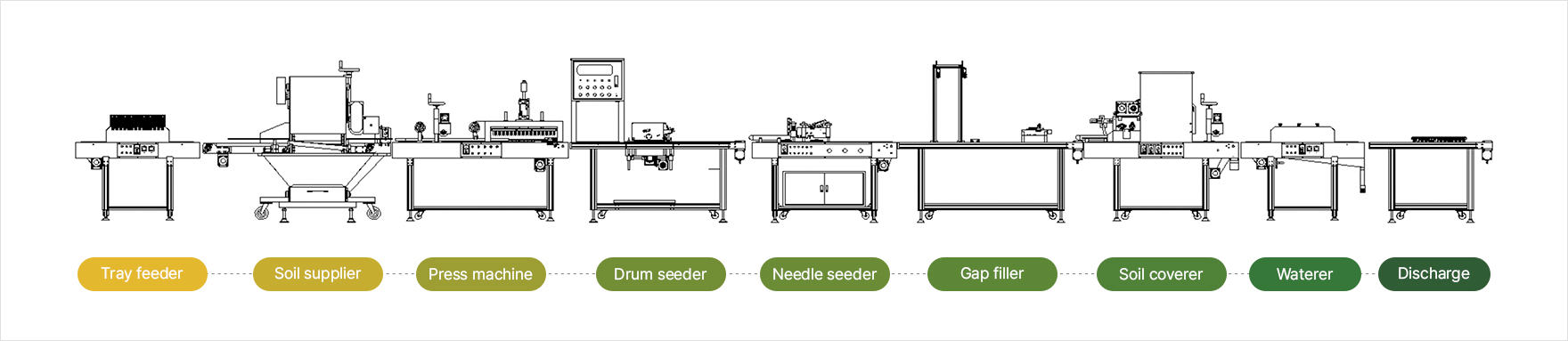

Seeder

Entire seeding process

Core process

Due to the missing seed issue of conventional seeders, the actual seeding rate is 80%, and to solve the space utilization problem caused by gaps, we developed a gap filler that maintains a seeding rate of over 97%.

- Variable method is adopted to enable various tray custom settings from 32 to 162 cells

Spec

- Production

speed -

- Drum : max 450 tray/hour

- Niddle : max 300 tray/hour

- Seeding rate

-

- 97% or higher

- Seeder Size

-

- W2.5m x L12.0m x H1.6m

(excluding high-capacity soil supplier)

- W2.5m x L12.0m x H1.6m

- Tray Size

-

- max 400 x 700 mm (changeable)

- Utility

-

- 220V / 380V 3-phase

- CAD 6bar

- Irrigation line

- Drainage line

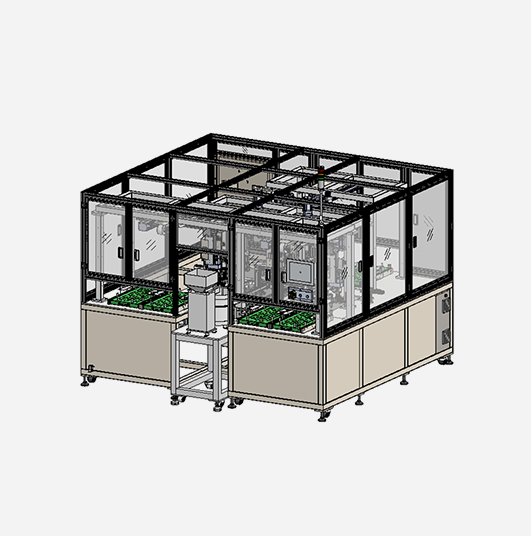

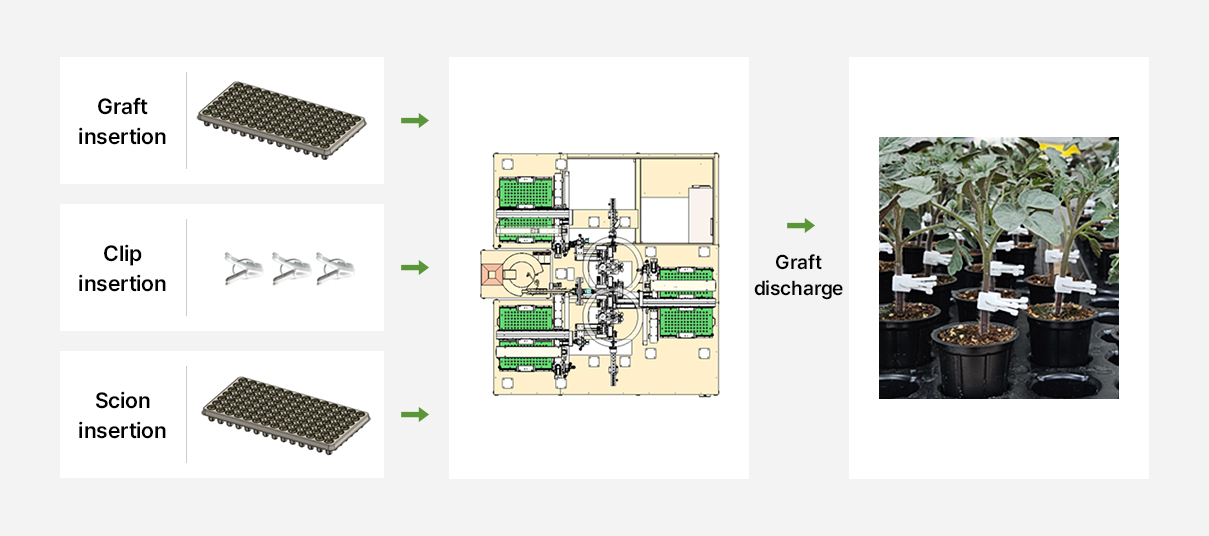

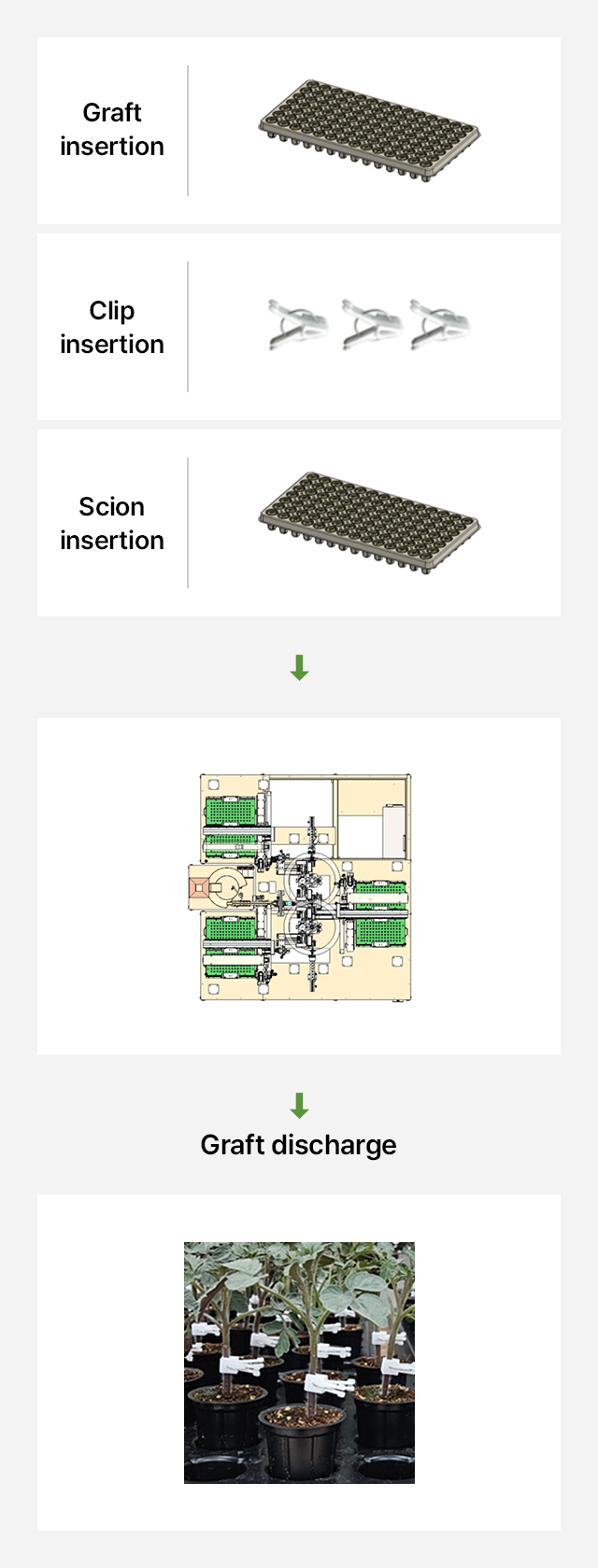

Grafting machine

Core Process

The core technology behind this grafting machine is based on TWIM's vision inspection technology and accumulated expertise. It analyzes the position, curvature, and end-point alignment between the scion and rootstock to achieve optimal alignment.

Product photos

Skilled grafting technicians

- Average

- 15SEC

- Success Rate

- 95%

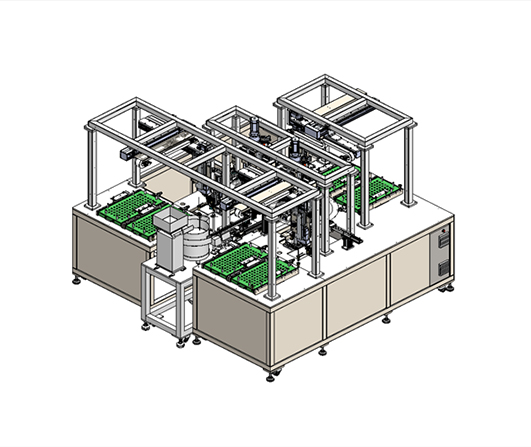

KOREA STANDARD SEEDLING's grafting machine

- Average

- 8SEC

- Success Rate

- 90%

Spec

- Production

speed -

- 450 plants/hour

- Grafting rate

-

- 90% or more

- Grafting machine

Size -

- W2.8m x L2.6m x H2.0m

- Utility

-

- 220V 3 phase

- CAD 6bar

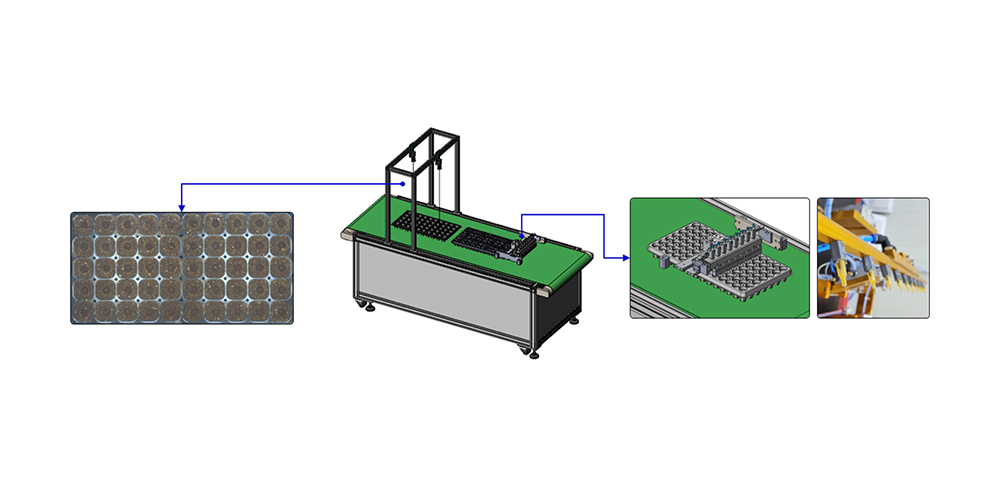

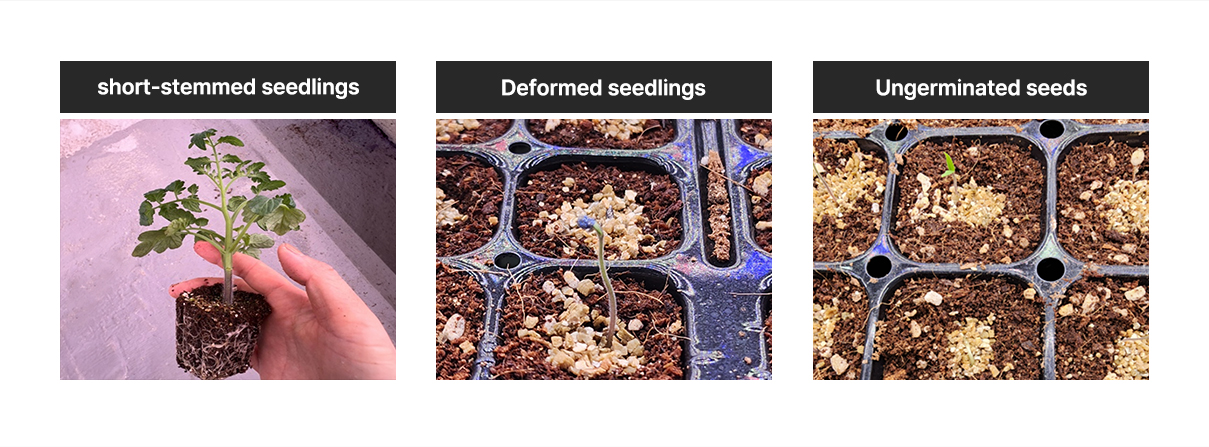

Sorter

Core technology

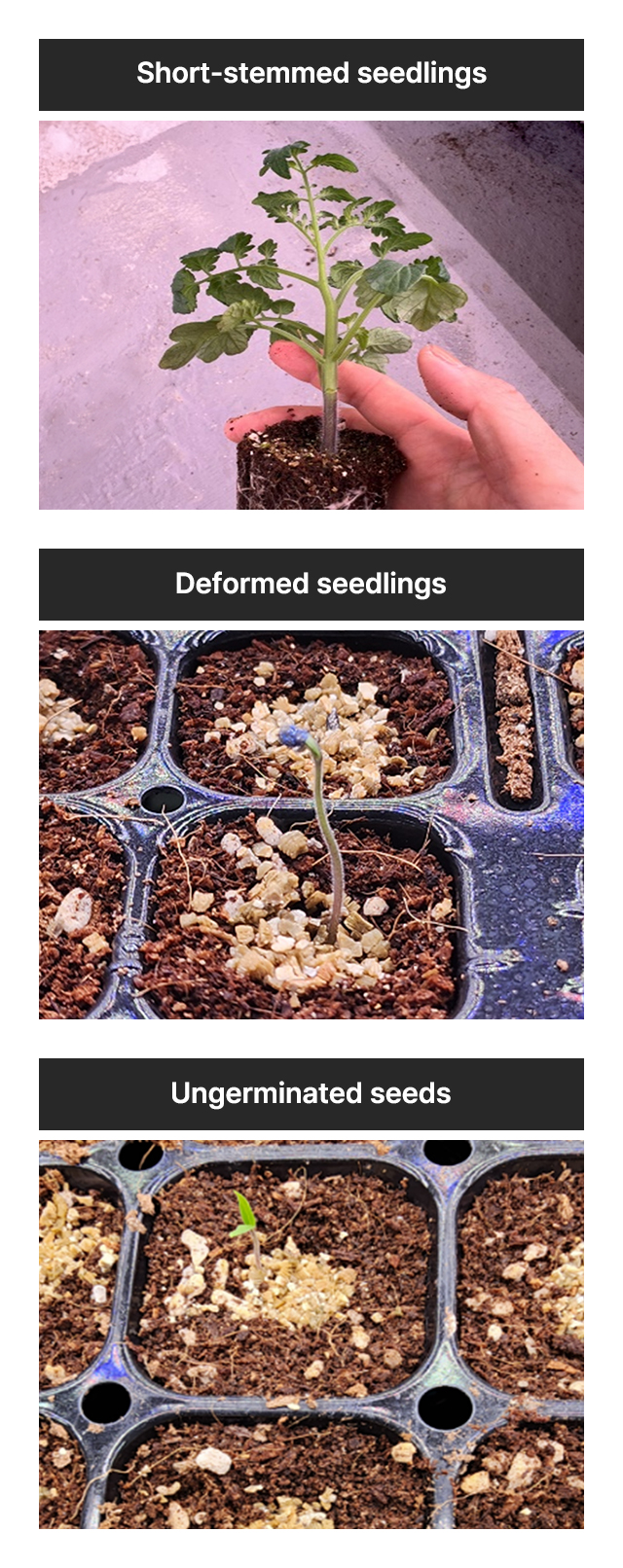

Through vision, the growth status is monitored and abnormal, short-stemmed, ungerminated, optimal grafting status, etc. are judged and selected.

Product photos

The sorting categories of the sorter are listed below

- 01

- Sorting of ungerminated seeds, seeds with hulls, 1or incomplete dehulling

- 02

- Sorting of short-stemmed seedlings

- 03

- Sorting of deformed seedlings

- 04

- Evaluation of grafting compatibility and stem diameter

- 05

- Cotyledon removal

- 06

- Assessment of seedling nutrition and overall health

Spec

- Production

speed -

- 450 plants/hour

- Sorting

Criteria -

- Separate discharge of A, B, C grades

- Sorter Size

-

- W2.6m x L1.6m x H2.0m

- Utility

-

- 220V 3-phase

- CAD 6bar